All filter bags are made with excellent quality materials, accompanied by a German BIA certification: polyester fibers, Nomex, Rayton, P84, polypropylene, acrylic, aramid, as well as a wide range of finishes (Teflon, hydro and oil- repellency, flame retardant, antistatic, anti-hydrolysis, non-stick just to name a few).

Filter sleeves

Millimetric precision for a complete product

In addition to the filter bags, we also provide our customers with one complete set of accessories: from Venturi tubes (in plastic, aluminum or stainless steel), to rotating nozzles for cleaning the cartridges available in different heights, from differential pressure gauges for reading the pressure drop to precoating or fluorescent powders, up to the sleeve-tightening and bag-tightening bands.

Discover the products

Sleeves and pockets

What technologies do we use?

- Automatic blade cutting with CAD/CAM.

- Automatic tubing lines for cutting and tubularisation of felts and fabrics by heat sealing.

- Line able to offer millimetric precision and very high reliability.

- Manipulators for automatic folding and continuous packaging.

Filter sleeves

Download the catalog to discover the project, the filtering fabrics and the Bag series coding system.

Project

- Chemical behavior and properties of fibers

- Standards for the control of filter fabrics

- Information for sizing the air / fabric ratio

- List for sizing the air / fabric ratio

- Information for a correct explosion risk assessment extracted from the ATEX regulation

Bag series coding

- Series

- Diameter

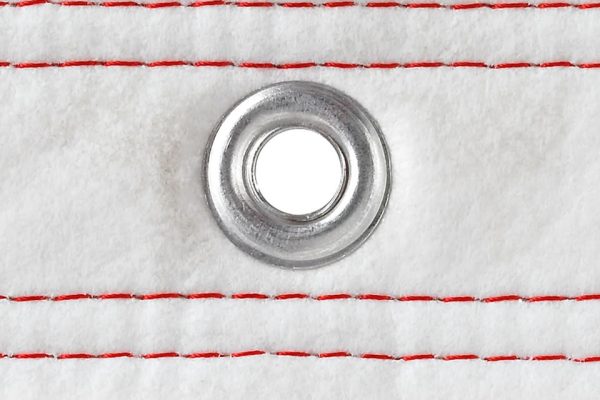

- Type of fastening (with useful explanatory drawings)

- Sleeve height

- Filter fabric