At our Leinì plant we have an in-house laboratory dedicated to the analysis of filter materials and dust.

We analyze, for example, exhausted filter fabrics to understand how the fabric itself worked during the filtration process: in this way we are able to process data on particles and clogging level.

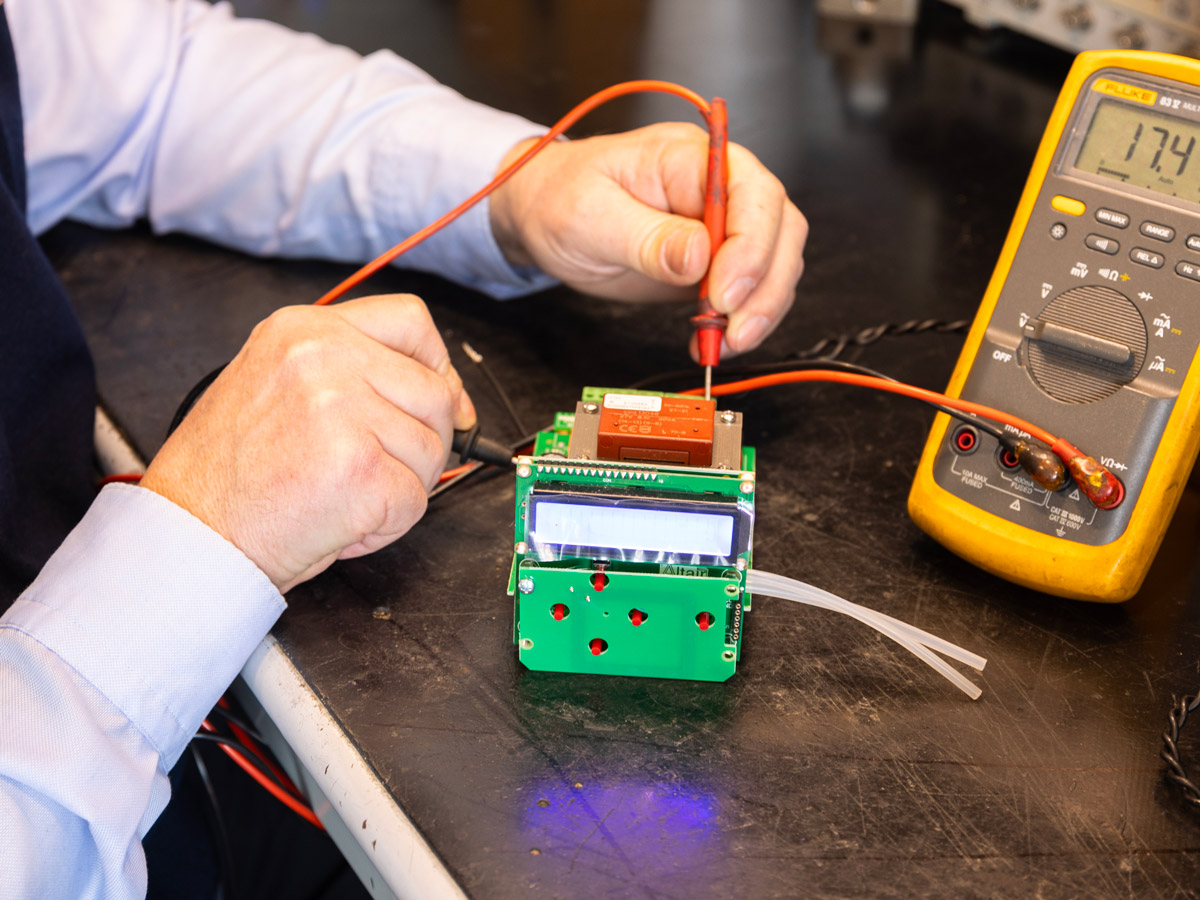

All this is done with top-notch instrumentation: we are equipped with a permeability meter, an electron microscope, and an electronic scale, among others.

Hand in hand with material analysis, we are able to perform different tests: from fluorescent powder testing to permeability testing, from electrical conductivity testing to high-temperature resistance testing: the necessary to further improve our final product.